Hot Sale Wood Sawdust Mill Fuel Briquette Making Machine Hydraulic Wood Biomass Piston Press Machine Manufacture

Product Description

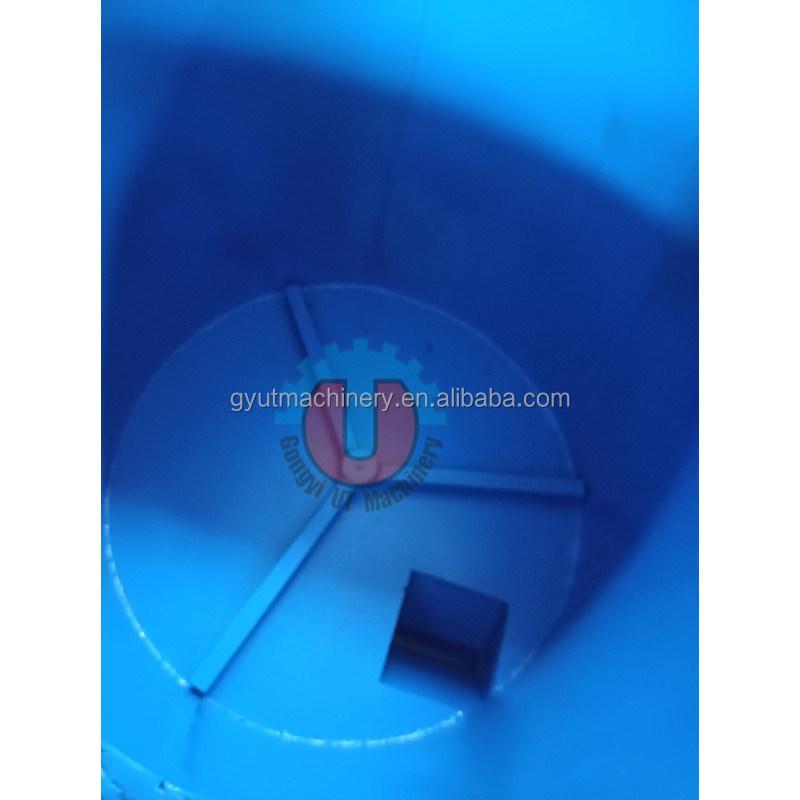

1. Brief introduction of wood Fuel Briquette Making Machine Hydraulic Wood Biomass Piston Press Machine Manufacture:

Raw Material → Crusher → Dryer → Briquette machine→Carbonization Furnace.

The whole charcoal production line mainly includes four needed machines: crusher, dryer, briquette making machineand carbonization furnace.

2. Technical parameters of Fuel Briquette Making Machine Hydraulic Wood Biomass Piston Press Machine Manufacture:

| Model | Capacity (t/h) | Motor Power (kw) | Diesel Power (hp) | Inlet Size (mm) | Disc Diameter (mm) | Blades Qty (pcs) |

| 500 | 0.8-1 | 5.5-7.5 | 12-15 | 150*150 | 400 | 4 |

| 600 | 1-2 | 11 | 20 | 200*200 | 500 | 4 |

| 700 | 2-3 | 15 | 30 | 250*250 | 600 | 4 |

| 800 | 3-3.5 | 18.5-22 | 45 | 300*300 | 700 | 4 |

| 900 | 3.5-4 | 37 | 50 | 350*350 | 800 | 4 |

| 1000 | 4-5 | 45 | 55 | 400*400 | 900 | 4-6 |

| 1200 | 5-6 | 55 | 75 | 450*450 | 1000 | 4-6 |

4. Advantages of Fuel Briquette Making Machine Hydraulic Wood Biomass Piston Press Machine Manufacture:

1). Wide application:

This machine can be widely used in paper inudstry, can be the previous work of wood charcoal production line and wood pellet production line, also can be used in breeding industry;

2). High quality mateirals made:

This wood processing machine is made of high manganese carbon steel, which has the features of anti-corrosion, longer service life, etc. Further, this series machine cutter is made of high quality alloy.

3). Save cost:

Compact and simple structure, so it can save your area occupying cost;

Made of high quality steel, so it can save your maintaince cost and spare parts cost;

Raw material of wood pellets fuel making machine Hydraulic Wood Biomass Piston Press Machine Manufacture::

1. Applicable raw material:

The raw materials of wood sawdust briquettes manufacturing machines can be wood material like sawdust, wood branches, leaves, bamboo, etc; agricultural waste such as: surgarcane, bagasse, rice husk, corn stalk, corn cob, grain stems, etc; fruit shells: peanut shell, coconut shell, coffee husk, etc.

2. Requirements of raw material:

1). The inlet size of raw material must be less than 3mm. If the raw material size are bigger, you must crush them with wood crusher firstly. The smaller the raw material, the smoothly the briquettes surface, and the better the hardness and strength.

2). The moisture of raw material for briquetting, must be less than 12%, and the moderate is 8%-12%, otherwise, the outlet briquettes are easily broken and have crevice. So before briquetting, you shall check the moisture content, if too wet, please drying them with sawdust dryer or under shunshine.

other mold of Fuel Briquette Making Machine Hydraulic Wood Biomass Piston Press Machine for choose

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!